Abrasive blasting stands as a pivotal process in surface treatment, where the efficiency and outcome largely depend on the quality of the operating mix. This mix, a dynamic combination of abrasive particles, plays a key role in determining the efficiency and effectiveness of the blasting process.

The Critical Role of the Operating Mix

The operating mix used in abrasive blasting is far from static. Over time, the abrasives alter in shape and size, evolving into what we refer to as the operating mix. This mix, comprising varying sizes of particles, must be meticulously balanced. A mix leaning towards larger particles might extend cleaning times, while one with predominantly finer particles may fall short in effectiveness. Achieving an optimal balance, where cleaning is both rapid and efficient, is crucial.

Optimizing with Precision Tools

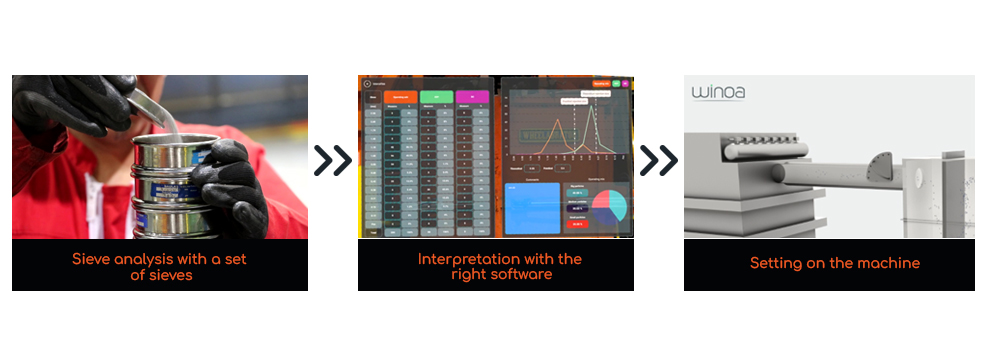

Accurate control of the operating mix is essential for optimal blasting results. The [Blast Check Kit], for instance, is an invaluable asset for evaluating the current state of your abrasives, ensuring that your mix is conducive to efficient cleaning. For a more detailed analysis, the [Sieving Kit] can be used to assess the size distribution of your abrasive particles, helping you understand and adjust your mix for peak performance. Additionally, the [Pocket Scale] is perfect for quick, on-the-go assessments, enabling you to maintain the right mix balance at all times.

Leveraging Expertise through Consulting Services

While the right tools are indispensable, expert advice can further enhance your blasting processes. Our offer tailored solutions to refine your abrasive blasting operations. Our team of seasoned experts provides insights and recommendations to optimize every aspect of your process, from the operating mix to machine settings.

Conclusion

Mastering your operating mix in abrasive blasting is a nuanced endeavor. With tools like the Blast Check Kit, Sieving Kit, and Pocket Scale, combined with expert guidance from our consulting services, you can ensure your blasting operations are as efficient and effective as possible. Embracing these resources is a step towards achieving excellence in your abrasive blasting procedures.