Two commonly used hardness scales are the Vickers Hardness (HV) and Rockwell C Scale Hardness (HRC). Each method offers advantages and is suitable for different types of materials and applications. This article delves into the differences between HV and HRC, their testing procedures, how to choose the right scale for your needs, and the role of products like steel shot, steel grit, cut wire, and AMS shot in hardness testing.

What is Hardness Testing?

Hardness testing measures a material's resistance to deformation, typically by indentation. This property is essential for determining the material's suitability for various applications, including wear resistance, strength, and durability. By understanding hardness, engineers and manufacturers can ensure that materials meet the required standards for specific uses.

Vickers Hardness (HV)

The Vickers Hardness test employs a diamond indenter to make an impression on the material's surface. The test involves pressing a diamond pyramid indenter with a square base and an angle of 136 degrees between opposite faces into the material at a specific force. The size of the resulting indentation is then measured to calculate the hardness value. This method is advantageous because it applies to all types of materials, both hard and soft, providing a continuous scale of hardness. It is particularly suitable for thin materials and coatings, making it ideal for microhardness testing and research and development applications.

Rockwell C Scale Hardness (HRC)

The Rockwell Hardness test measures the depth of penetration of an indenter under a large load compared to the penetration made by a preload. The Rockwell C Scale specifically uses a diamond cone indenter. During testing, a preliminary test force (minor load) is first applied to set the indenter in position, followed by a major load. The depth of the indentation is then measured, and the HRC value is determined. This method is quick and easy to perform, requiring minimal material preparation, making it highly suitable for quality control and production environments. It is commonly used for testing harder materials such as steel and other metals.

Key Differences Between HV and HRC

The primary differences between HV and HRC lie in their testing procedures and applications. HV uses a diamond pyramid indenter and measures the size of the indentation, making it versatile and applicable to all materials, including thin films. In contrast, HRC uses a diamond cone indenter and measures the depth of the indentation, typically applied to harder materials like metals. This makes HRC more suitable for industrial applications where quick and easy testing is required.

Choosing the Right Hardness Scale

Selecting the appropriate hardness scale depends on the material type and testing needs. For thin materials, coatings, and a broad range of hardness levels, HV is the preferred choice due to its detailed and precise measurements. On the other hand, for harder materials like steel, HRC is more advantageous due to its simplicity and speed, making it ideal for industrial settings.

Role of Metallic Abrasives in Hardness Testing

The choice of abrasives significantly influences the effectiveness of hardness testing and surface preparation.

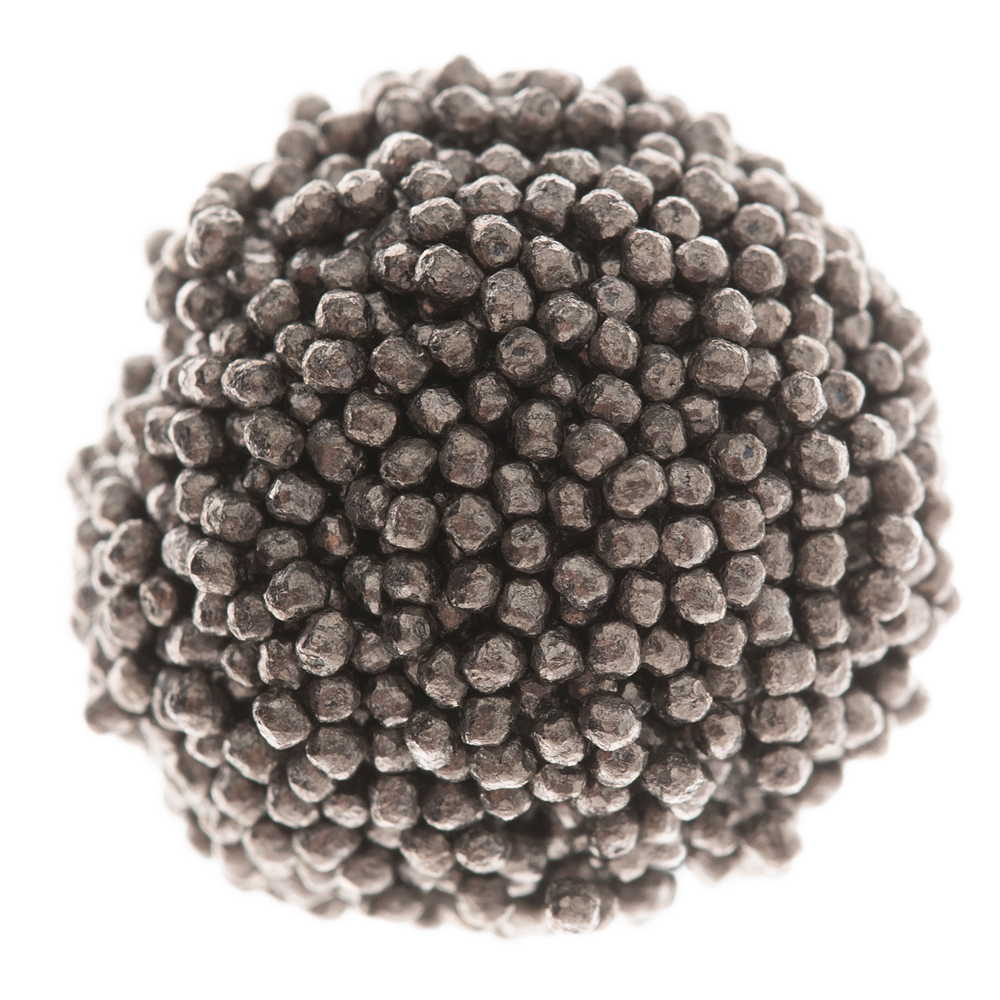

Steel shot, with a typical hardness range of 40-50 HRC, is used for cleaning, descaling, and surface preparation for medium to high hardness applications. Steel grit, with a hardness range of 40-65 HRC, provides aggressive cleaning action suitable for deep surface penetration and profile creation. Cut wire, ranging from 40-55 HRC, is ideal for precision shot peening, improving fatigue resistance while maintaining consistent size and shape. AMS shot, designed for high-precision applications like aerospace, typically ranges from 55-62 HRC, ensuring minimal contamination and superior surface quality.

Expert Guidance

Hardness testing can be complex, and selecting the appropriate method depends on various factors, including material type and application. Consulting with experts in the field can provide valuable insights and ensure that the testing process is optimized for your specific needs. Professionals provide critical insights into selecting the right abrasives and optimizing process parameters, ensuring superior surface quality and enhanced performance.