Surface preparation in metalworking is a process with a dual aim: removing scale or rust from the metal part and generating the best possible surface profile for coating adhesion. This preparation is essential for the application of paint or a plastic layer, ensuring durability and longevity of the coating.

Understanding the Importance of Surface Preparation

Scale and rust can significantly compromise the quality of metal parts. Their presence not only detracts from the metal's appearance but also weakens its structural integrity. Moreover, an uneven or improperly prepared surface can lead to poor adhesion of coatings, resulting in peeling, flaking, or corrosion over time.

The Role of Abrasive Media

To achieve the desired level of surface cleanliness and texture, a range of abrasive products like GP50 to GP25, GL50 to GL25, GH50 to GH25, Profilium, Prowheelium, Stainium, and Surfium are used. These abrasives are selected based on their grit size, material, and compatibility with the metal being processed.

1. Blasting Techniques for Scale and Rust Removal

Abrasive blasting is a common method for removing scale and rust. This process involves propelling abrasive media at high speeds onto the metal surface, effectively cleaning it. The choice of abrasive, pressure, and angle of blasting are critical factors that determine the efficiency and effectiveness of the process.

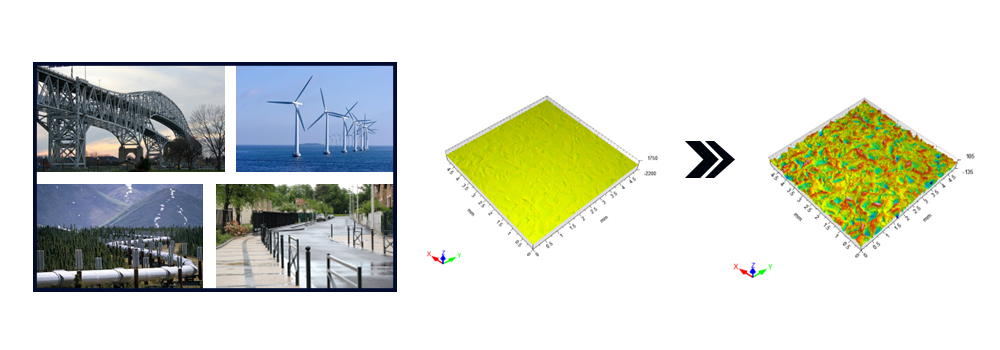

2. Achieving the Right Surface Profile

For coatings to adhere properly, the metal surface needs a specific texture or profile. This is where products like Profilium, Prowheelium, Stainium, and Surfium come into play. They are designed to create a uniform surface profile that enhances coating adhesion.

3. Types of Machines Used

Different types of machines are used for surface preparation, depending on the size and shape of the metal parts. These machines are designed to handle various abrasive media and can be adjusted for different levels of abrasiveness, ensuring that the surface is prepared precisely to the required standards.

Conclusion

Proper surface preparation is key to the success of any metalworking project. Understanding the use of different abrasive products and techniques for creating the ideal surface profile is essential for achieving a high-quality, durable finish on metal parts.