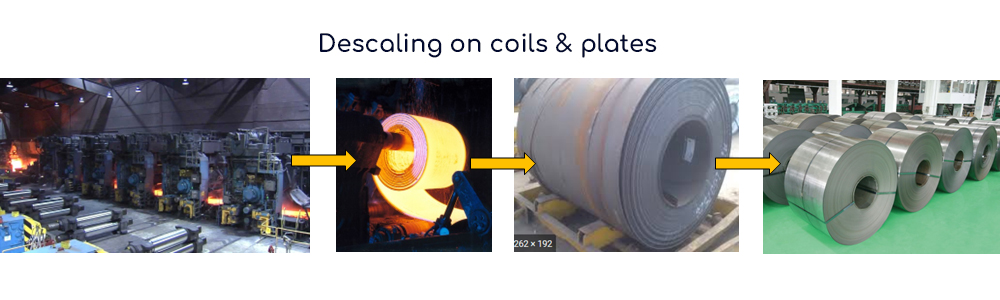

Descaling in the metalworking industry, especially for coils and plates, is a vital process post-lamination. After being subjected to high temperatures during lamination, coils and plates often develop a layer of scale on their surface. This scale, if not removed, can hamper further processing and affect the quality of the final product. While acid bath treatments are commonly used, blasting is essential to maximize scale removal and prolong the life of these acid baths.

The Challenge of Scale on Coils and Plates

Scale formed during lamination is not just a surface blemish; it represents a significant barrier to quality and efficiency. The acid bath, while effective, can become less efficient over time due to scale buildup. Therefore, additional mechanical descaling methods are crucial.

1. The Role of Blasting in Descaling

Blasting employs abrasive materials like S170, S110, GP50, and Stainium to forcefully remove scale. This process ensures a more thorough cleaning, reducing the load on acid baths and extending their service life.

2. Selecting the Right Abrasives

The choice of abrasives is critical. Each abrasive, from S170 to Stainium, offers different levels of abrasiveness and is chosen based on the thickness and tenacity of the scale, as well as the sensitivity of the metal surface.

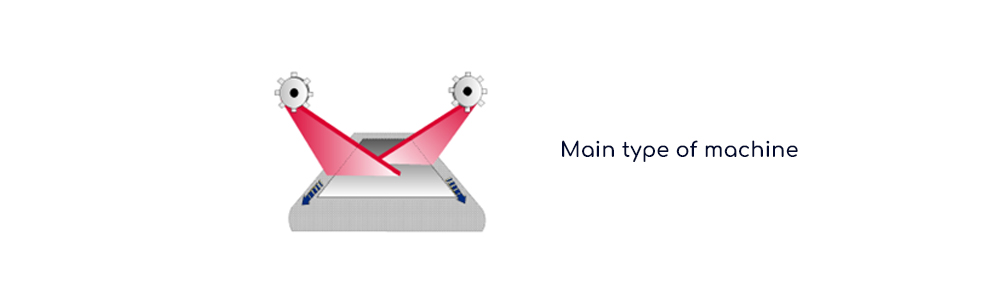

3. Types of Descaling Machines

Specific machines are designed for descaling coils and plates. These machines cater to the size and shape of the coils and plates, ensuring efficient and uniform scale removal across the entire surface.

Conclusion

Descaling on coils and plates is a main step in ensuring the quality of metal products post-lamination. Understanding the importance of blasting, alongside acid bath treatment, and the use of the right abrasive materials and machinery, can significantly enhance the efficiency and cost-effectiveness of the descaling process.