Shot peening is a critical process in the manufacturing and maintenance of steel parts, particularly those subjected to cyclic tension and compression. Steel, while highly resistant to compression, is vulnerable to cyclic tension, which can lead to surface cracks and eventual breakage. Shot peening addresses this challenge by creating an artificial compressive stress on the surface of steel parts, thereby extending their lifetime and allowing for lighter parts with equivalent performance.

Understanding Shot Peening

Shot peening involves bombarding the surface of steel parts with small spherical shots, typically ranging from S110 to S460, including UFS (Ultra Fine Shot). This bombardment leads to a layer of compressive stress on the part's surface. The compressive stress acts as a barrier, preventing the initiation and propagation of cracks that could arise from cyclic tension.

1. The Process of Shot Peening

The process involves propelling shots at the steel surface at high velocity. Each shot acts like a tiny hammer, deforming the surface slightly and inducing compressive stress. The coverage and intensity of shot peening are carefully controlled to ensure uniform stress distribution without damaging the part.

2. Choice of Shots and Their Impact

The choice of shots, from S110 to S460 and UFS, is crucial. Factors like shot size, material, and hardness must be matched to the part's material and the desired compressive stress level. Smaller shots are used for finer finishes, while larger shots provide deeper compressive stress.

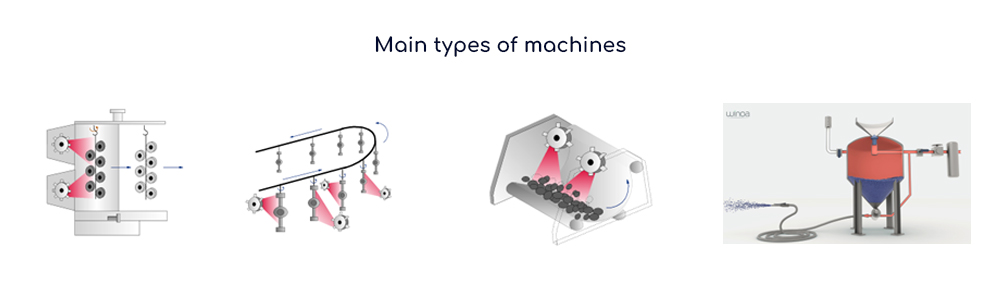

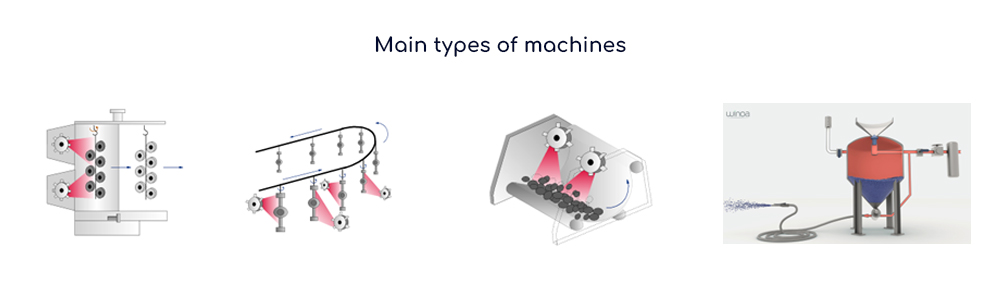

3. Types of Machines Used in Shot Peening

Various types of shot peening machines are utilized, tailored to the size, shape, and material of the parts. These machines ensure consistent shot flow and velocity, crucial for achieving the desired compressive stress across the entire surface of the part.

Conclusion

Shot peening is a vital process in extending the life of steel parts exposed to cyclic tension. By creating an artificial layer of compressive stress, it prevents the formation of surface cracks, resulting in more durable and potentially lighter parts. Understanding the process, choice of shots, and machinery involved is key to optimizing the benefits of shot peening in metalworking.