TCO, Winoa's pillar of differentiation

The TCO (Total Cost of Operation), or the "Total Cost of Operation" of sandblasting, is one of the pillars of Winoa's differentiation.

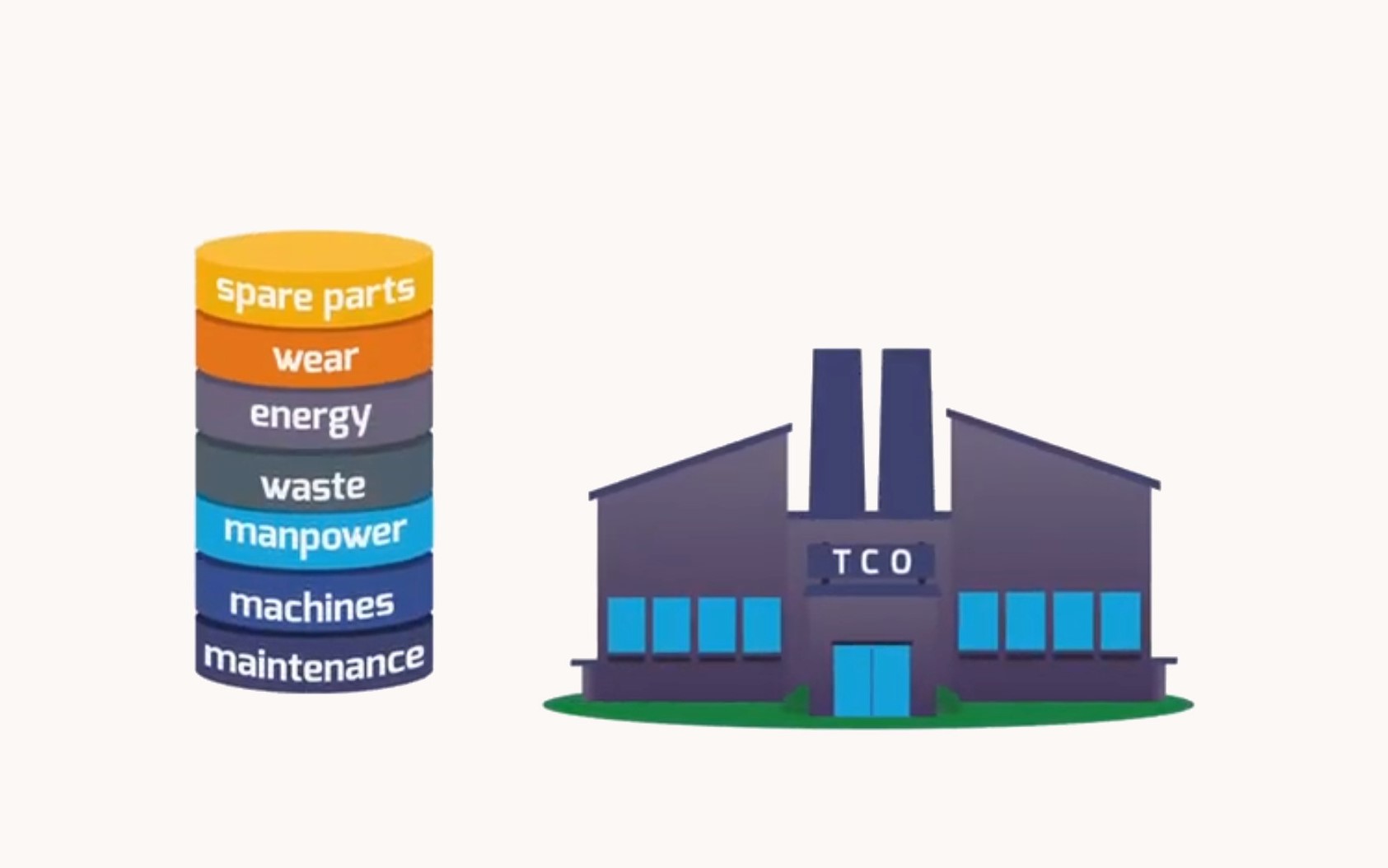

Most companies think they can reduce the cost of blasting operations by buying cheaper abrasives. The problem is that, in reality, abrasives represent only 20% of the total cost of shot-blasting operations: therefore even a reduction in the purchase cost of the shot has little impact on the overall cost of the process. Is there a more effective solution? Yes, considering all the elements involved: manpower, machines, maintenance, spare parts, wear, energy and waste, as well as the shot itself.

This is what W Abrasives' TCO approach does: a unique seven-step system that has already proven its worth to thousands of clients. We start by conducting an audit on the customer's equipment and blasting process, before deciding on a goal together. A series of tests are then carried out in one of the Winoa test centers to confirm that the targets are achievable, and then move on to work on the customer's plant. Then we go on to validate the forecast objectives and proceed with the training of customer’s team.

The strength of the approach lies in the fact that it is not a promise, but a clear and formal commitment that guarantees a quantified cost reduction.

W Abrasives is the global market leader and works with 10,000 companies around the world every day. All this made possible, with the TCO approach, to reduce the cost of sandblasting operations by an average of 11%.

Since its launch in 2001, over 3,000 customers have already optimized their costs. Why not join them?

Find out more about the TCO approach by watching this animation.