TCO, Winoa's pillar of differentiation

TCO, Winoa's pillar of differentiation

The TCO (Total Cost of Operation), or the "Total Cost of Operation" of sandblasting, is one of the pillars of Winoa's differentiation.

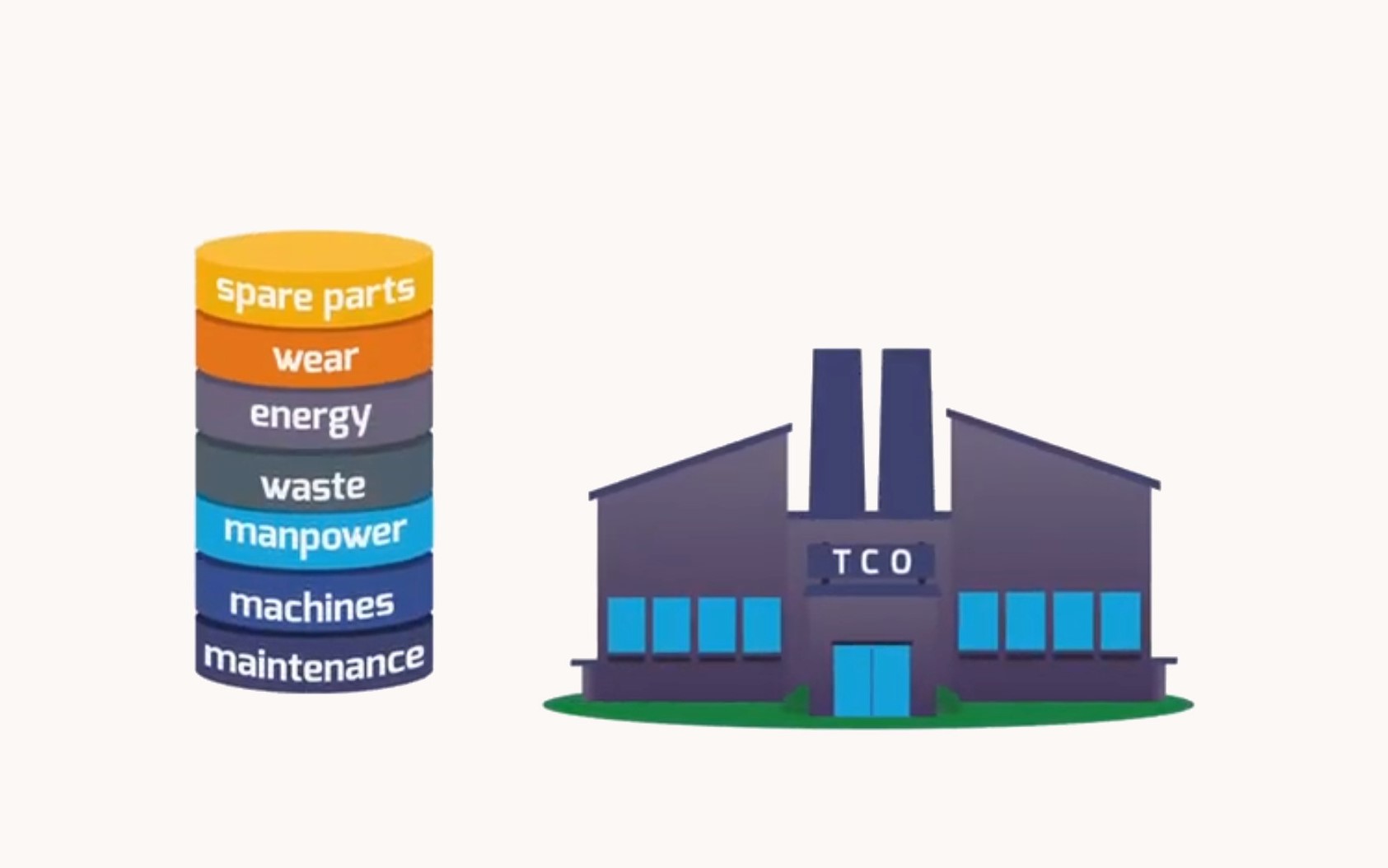

Most companies think they can reduce the cost of blasting operations by buying cheaper abrasives. The problem is that, in reality, abrasives represent only 20% of the total cost of shot-blasting operations: therefore even a reduction in the purchase cost of the shot has little impact on the overall cost of the process. Is there a more effective solution? Yes, considering all the elements involved: manpower, machines, maintenance, spare parts, wear, energy and waste, as well as the shot itself.