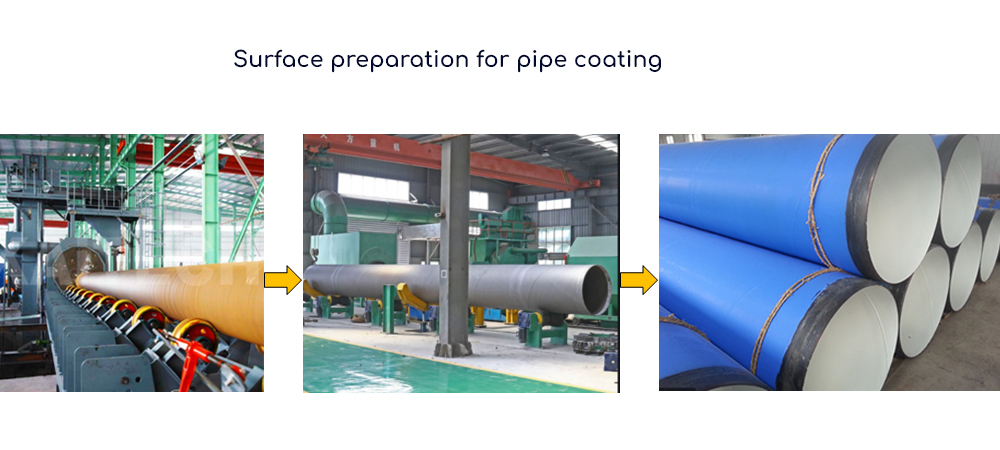

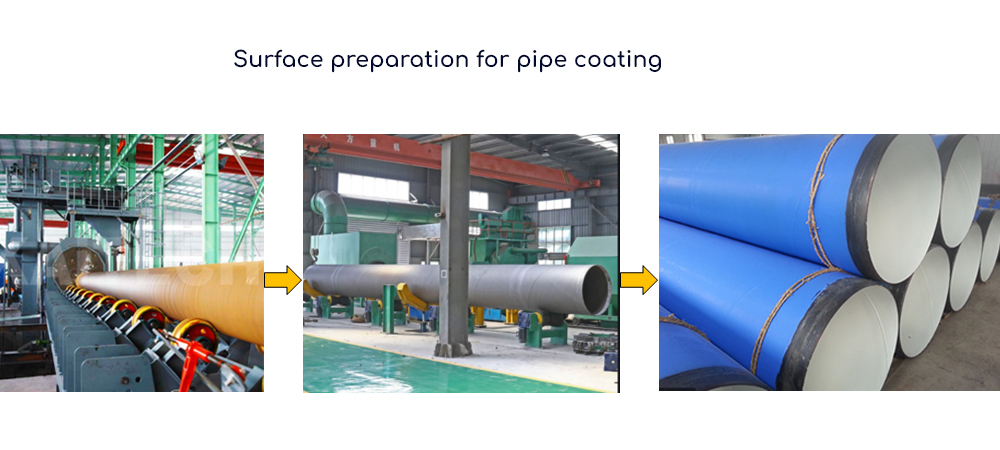

Surface preparation for pipe coating in the oil and gas industry is a process that demands precision and attention to detail. Given the industry's stringent requirements, where pipes are often expected to have a lifespan exceeding 25 years, every aspect of the preparation process becomes critical. The dual goals of this process are to remove any scale or rust and to create the most suitable surface profile for coating adhesion.

The Significance of Surface Preparation

In pipe coating, the stakes are high. The presence of oxides, dust, roughness, and soluble salts on the pipe's surface can significantly impact the quality and longevity of the coating. Therefore, the blasting process, which is employed for surface preparation, must be meticulously monitored and controlled.

1. Removing Scale and Rust

The first step in surface preparation is the removal of scale or rust. This is crucial for ensuring that the coating adheres properly to the pipe. Any failure in this step can lead to coating failure, which in an industry like oil and gas, can have severe implications.

2. Creating an Optimal Surface Profile

Once the scale and rust are removed, the next goal is to create an ideal surface profile. This involves achieving a specific level of roughness that allows the coating to adhere securely to the pipe. This aspect of surface preparation is where products like GL40, GL25, and Surfium play a significant role.

3. The Importance of Precise Monitoring

Due to the stringent specifications in the pipe coating industry, the blasting operation must be carefully monitored. This ensures that the surface preparation meets the required standards, laying the foundation for a durable and long-lasting coating.

Conclusion

Surface preparation for pipe coating is a process that cannot be underestimated, especially in industries where reliability and longevity are non-negotiable. By focusing on detailed and precise surface preparation, using the right products and techniques, the industry can ensure the safety and durability of its pipelines.