The production of steel abrasives is a complex, multi-step process that transforms raw materials into high-performance products for surface preparation and finishing. Understanding each stage of this process is crucial for appreciating the quality and characteristics of the final abrasive products. This guide provides an in-depth look at how steel abrasives are made, from the initial melting of scrap metal to the final packaging, highlighting the importance of quality control at every step.

The Steel Abrasive Production Process

The production of steel abrasives involves several critical steps, each contributing to the quality and performance of the final product. Here’s a step-by-step overview of the process:

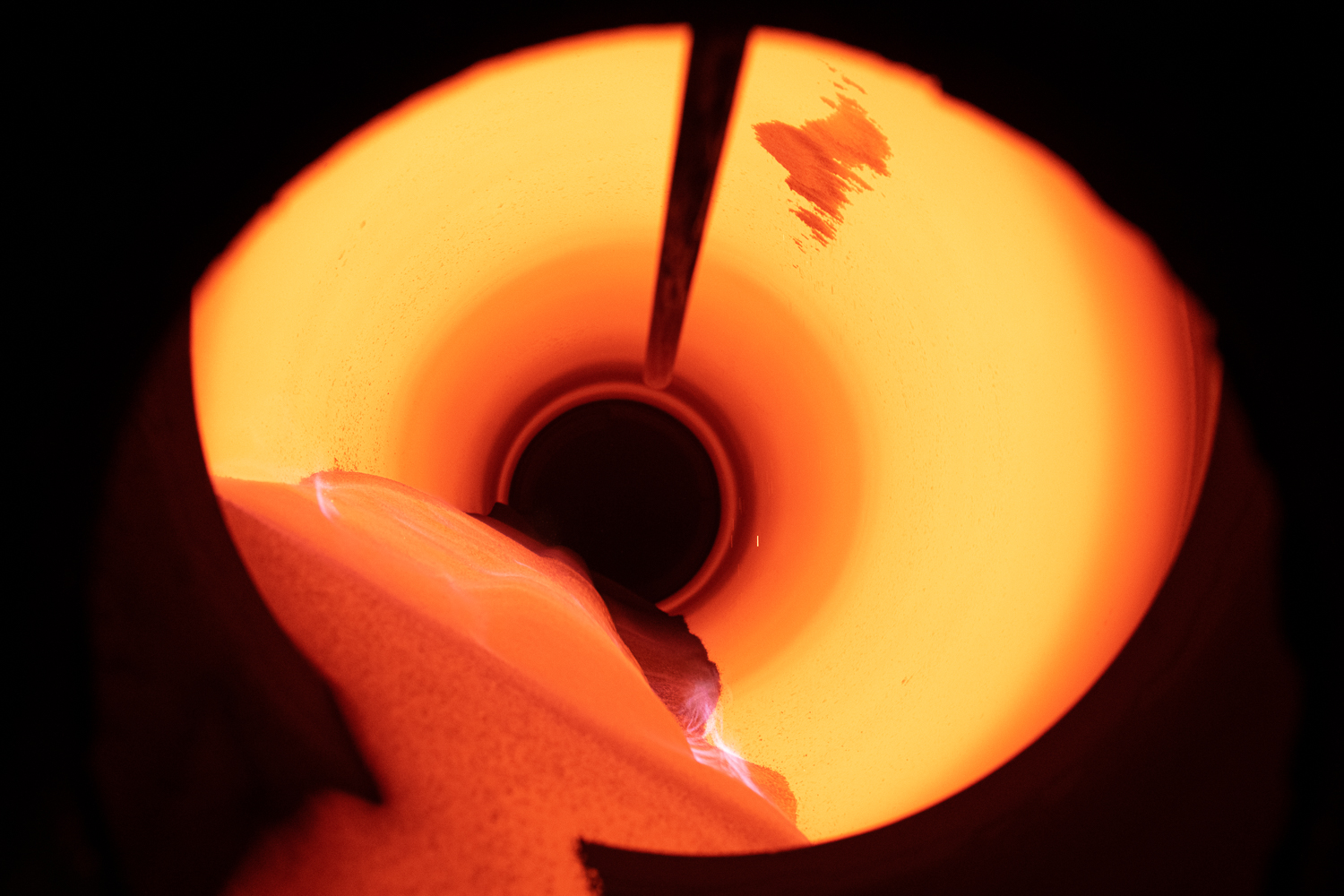

1. Melting and Fusion

The process begins with the melting of scrap metal in a furnace, where ferroalloys are added to achieve the desired chemical composition. This step is crucial for ensuring that the final product has the necessary mechanical properties, such as hardness and toughness.

Process: Scrap metal is melted and combined with ferroalloys in a furnace.

Importance: Establishes the foundational properties of the steel, such as hardness and toughness.

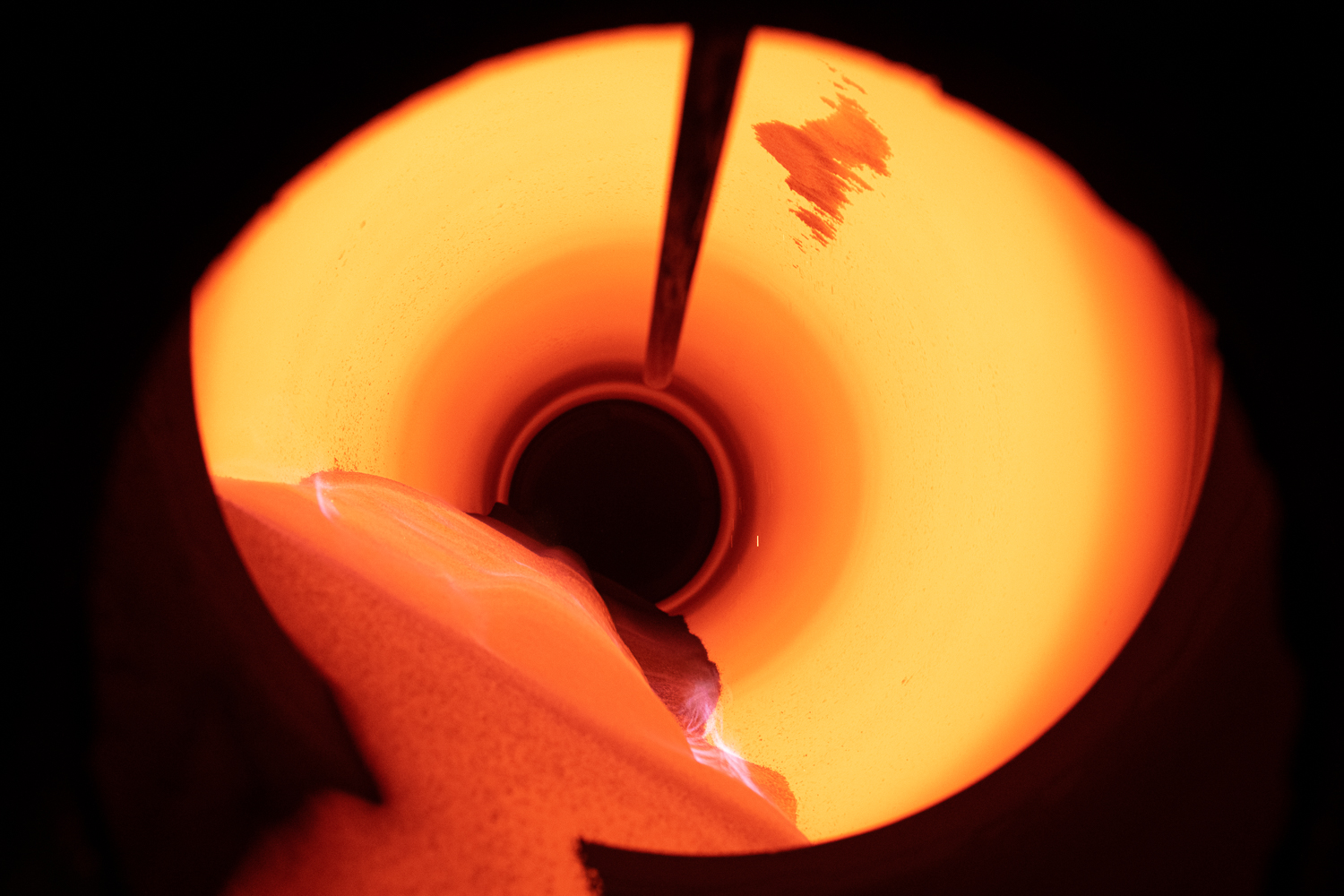

2. Atomization or Centrifugation

Once the metal is molten, it undergoes one of two processes to form the abrasive particles:

- Atomization: In this process, the molten metal is rapidly cooled by being sprayed with water or gas, breaking it into small, spherical particles. Atomization offers higher productivity but may result in a lower proportion of perfectly shaped particles.

- Centrifugation: Here, the molten metal is spun at high speeds, allowing the centrifugal force to shape the particles. This method produces more uniformly shaped particles but has lower productivity compared to atomization.

Process: Molten metal is either atomized or centrifuged to form abrasive particles. Importance: Determines the shape and uniformity of the abrasive particles, affecting performance and efficiency.

3. Quenching (Thermal Treatment)

After the particles are formed, they undergo quenching, a thermal treatment process designed to uniformize the crystalline structure of the steel. This step is essential for achieving the desired hardness and toughness in the abrasives.

Process: The abrasive particles are rapidly heated and cooled (quenched) to refine their crystalline structure.

Importance: Ensures uniform hardness and improves the overall durability of the abrasive.

4. Crushing (for Grit Production)

For the production of grit abrasives, an additional crushing step is necessary. During this stage, the abrasive particles are crushed to create angular shapes, which are particularly effective for aggressive surface preparation tasks.

Process: Abrasive particles are crushed to form grit with angular shapes.

Importance: Creates the sharp edges needed for aggressive surface preparation, such as descaling and rust removal.

5. Tempering (Secondary Thermal Treatment)

Tempering, also known as a secondary thermal treatment, follows quenching. This process slightly softens the abrasives to relieve internal stresses and adjust the hardness to the desired level. It’s important to note that the hardest grades, such as GH grit, do not undergo tempering.

Process: The abrasive particles are reheated to reduce hardness slightly and relieve stresses.

Importance: Balances hardness with toughness, ensuring the abrasives are durable yet not too brittle.

6. Quality Control

Throughout the production process, rigorous quality control checks are conducted at each stage to ensure that the abrasives meet the required specifications. These checks include verifying the chemical composition, particle shape, hardness, and overall quality of the product.

Process: Quality checks are performed after each production stage.

Importance: Guarantees that the final product meets industry standards and customer requirements.

7. Packaging

Finally, the abrasives are packaged according to customer requirements. Proper packaging ensures that the abrasives are protected during transportation and storage, preserving their quality until they are ready for use.

Process: Abrasives are packed into appropriate containers or bags.

Importance: Protects the abrasives from contamination and damage, ensuring they arrive at their destination in optimal condition.

Conclusion and Expert Guidance

The production of steel abrasives is a meticulously controlled process that transforms raw materials into high-performance products through a series of carefully executed steps, including melting, atomization or centrifugation, quenching, crushing, and tempering. Each stage is critical for ensuring the quality and effectiveness of the final abrasives. Rigorous quality control throughout the process guarantees that the abrasives meet stringent industry standards. However, achieving optimal results also depends on proper application and process adjustments. Partnering with experts who understand both the production and application of these abrasives can help you select the best products for your specific needs, ensuring superior performance and longevity in your operations.