In the specialized field of surface treatment, pre-stress or shot peening applications require precise control and understanding of the media used to achieve the desired outcomes on safety-critical parts. Non-metallic abrasives, such as ceramic beads and glass beads, play a pivotal role in these processes, offering unique advantages over traditional metallic abrasives. This article delves into the use of non-metallic abrasives for pre-stress treatments, underscoring the importance of expert guidance to optimize the blasting process.

Why Non-Metallic Abrasives for Pre-stress Treatments?

Pre-stress treatments like shot peening are essential for enhancing the fatigue strength and lifespan of components subjected to cyclic stress. Non-metallic abrasives, particularly ceramic and glass beads, are preferred for these applications due to their uniform shape, consistent hardness, and ability to impart a controlled, compressive stress layer without introducing surface contamination.

Ceramic Beads: Precision and Durability

Ceramic beads offer high durability and low breakdown rates, making them ideal for repeated use in shot peening applications. Their consistent size and shape ensure uniform coverage and intensity, critical for achieving precise compressive stress layers on components. The inherent properties of ceramic beads minimize the risk of introducing impurities to the treated surfaces, a crucial consideration for maintaining the integrity of components in aerospace, automotive, and other high-performance industries.

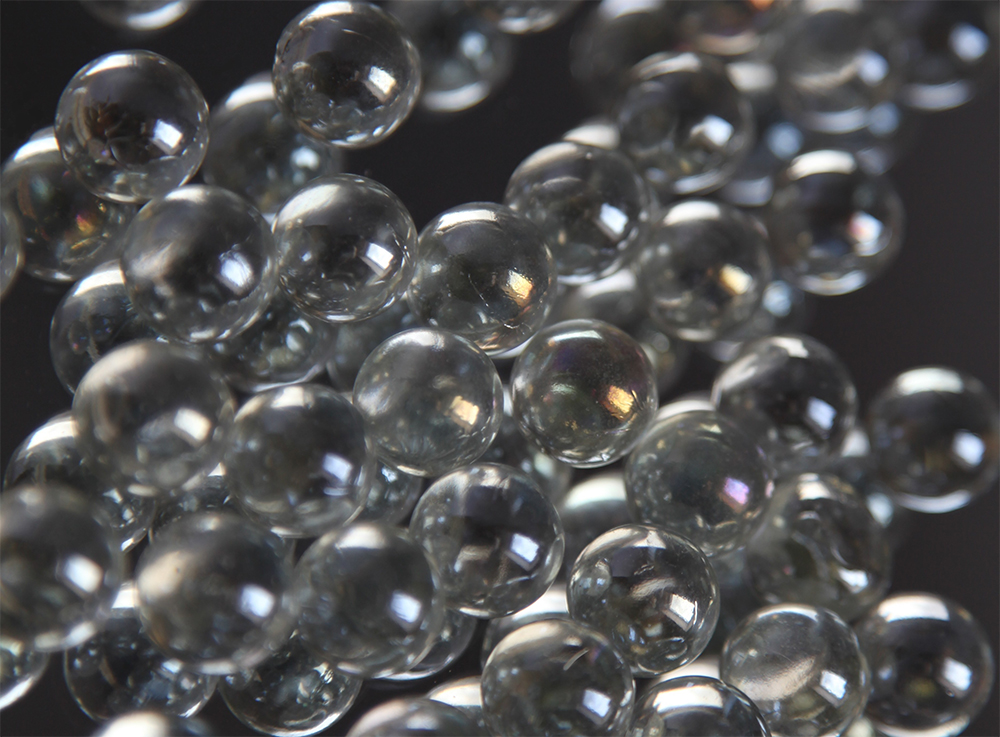

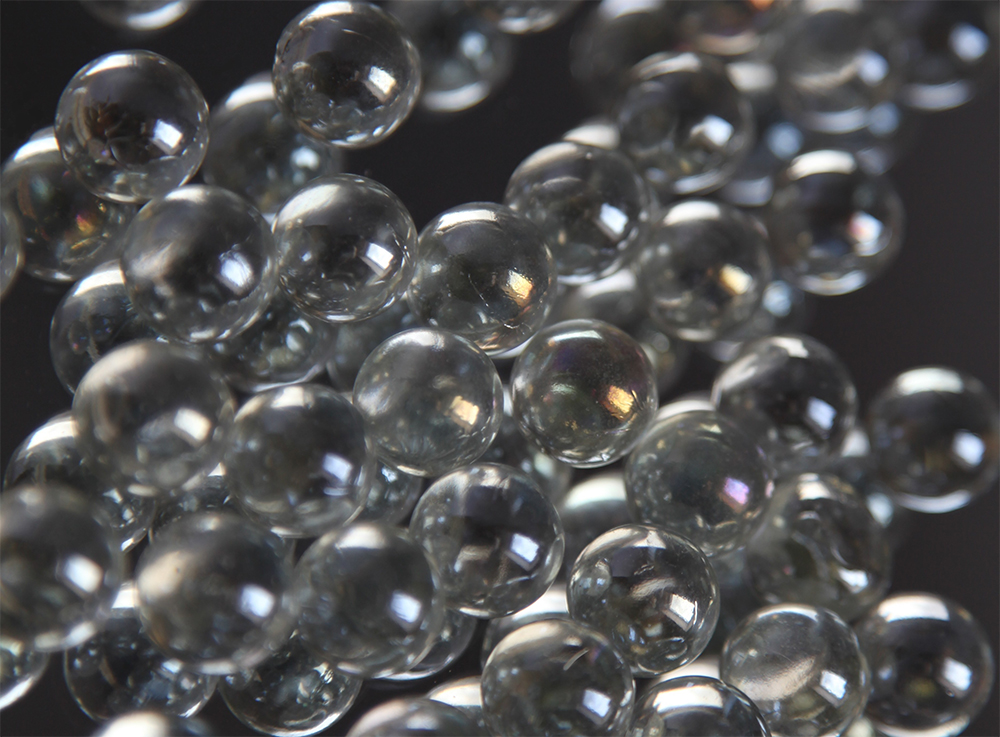

Glass Beads: Versatility and Surface Finish

Glass beads, known for their smooth surface and spherical shape, are effective in gently cleaning and pre-stressing surfaces without causing dimensional changes or introducing ferrous contamination. This makes them particularly suitable for applications where maintaining the original surface texture and integrity is essential. Glass beads are versatile, used not only for pre-stress treatments but also for achieving aesthetically pleasing finishes on a variety of substrates.

The Importance of Expert Guidance

Selecting the right abrasive media and optimizing the parameters of the pre-stress treatment process is complex, requiring a deep understanding of the material properties and the specific requirements of the application. Expert guidance is invaluable in navigating these complexities, ensuring that the chosen media and treatment method align perfectly with the goals of the application. Specialists in abrasive blasting can provide insights into the selection of ceramic or glass beads, adjustment of blasting parameters, and implementation of best practices to maximize the efficacy and efficiency of the pre-stress treatment.

Product Highlights

- Ceramic Beads: Ideal for applications requiring high durability and minimal media breakdown.

- Glass Beads: Best suited for applications where surface integrity and aesthetic finish are paramount.

Incorporating these non-metallic abrasives into pre-stress treatments under the guidance of experts ensures that components are prepared to the highest standards, ready to withstand the rigors of their operational environment.

Conclusion

The use of non-metallic abrasives like ceramic and glass beads in pre-stress treatments offers a range of benefits, from improved surface integrity to enhanced component longevity. By leveraging the unique properties of these abrasives and seeking expert advice, professionals can optimize their pre-stress treatment processes for superior outcomes. As the industry continues to evolve, the strategic selection of abrasive media will remain a cornerstone of successful surface treatment operations.