Non-metallic abrasives are valued for their ability to clean and finish surfaces without compromising the material's integrity. Their softer nature makes them ideal for applications where preserving the underlying surface is crucial:

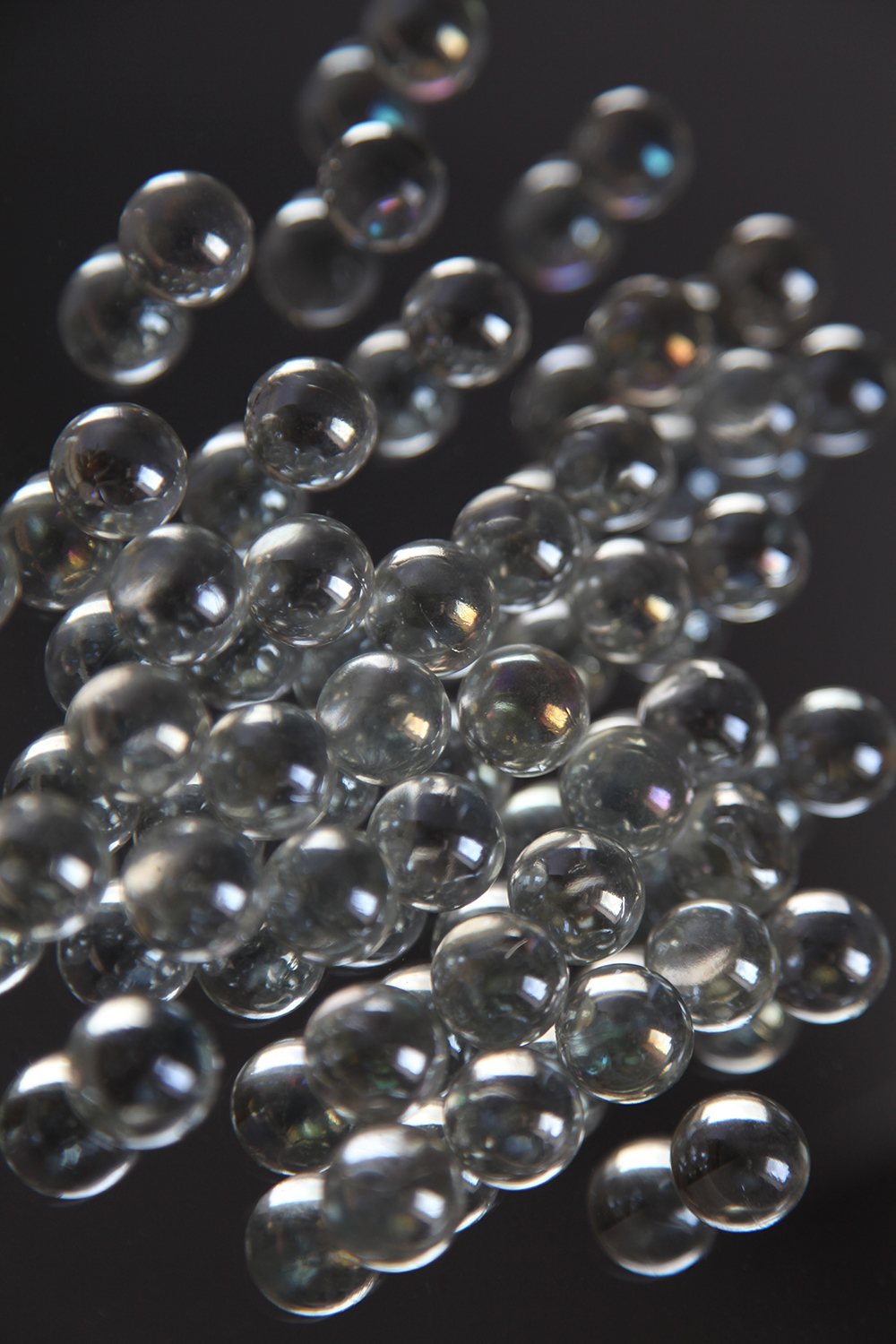

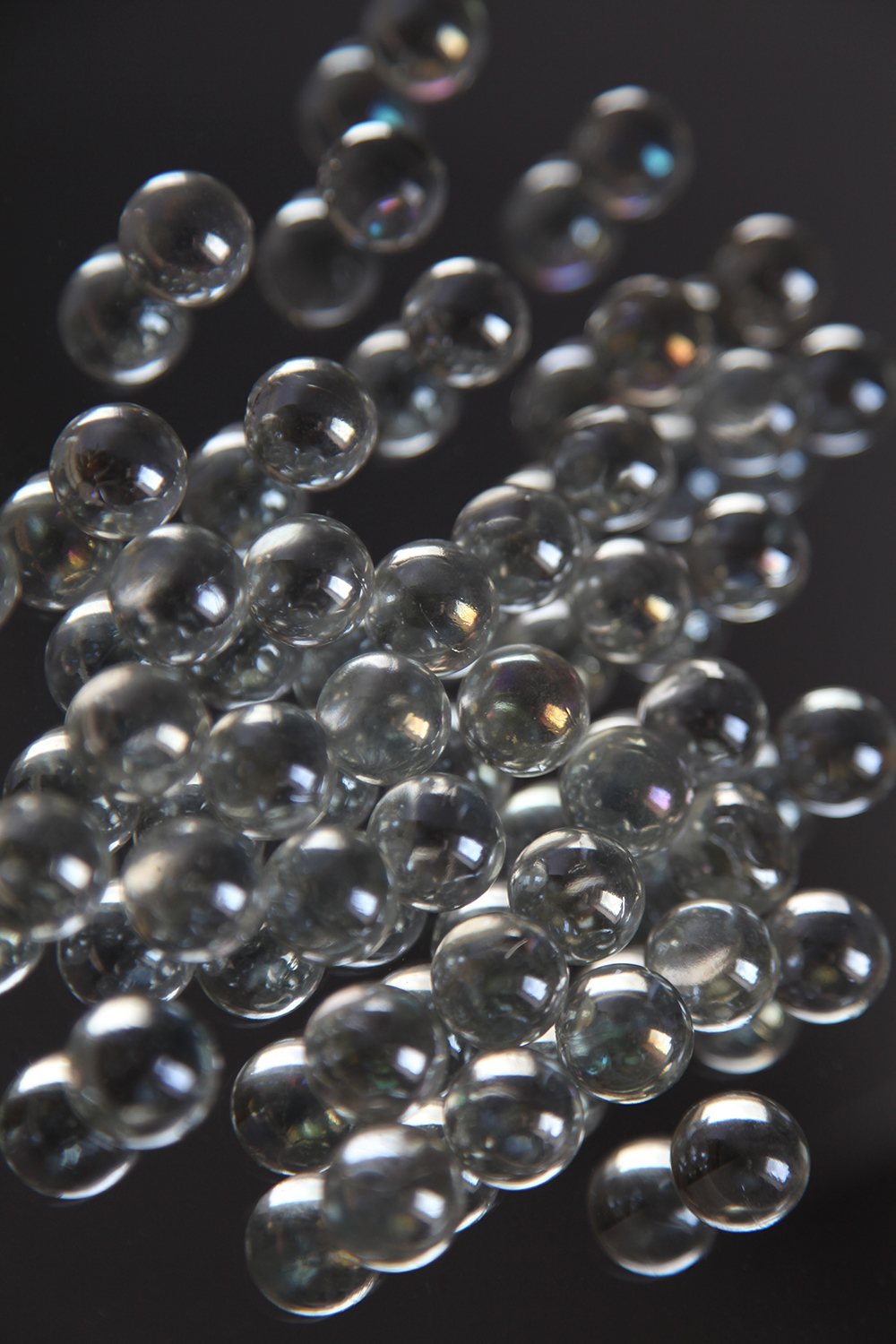

- Glass Beads and Plastic Media: Known for their gentle cleaning capabilities, glass beads and plastic media are perfect for achieving a smooth, satin-like finish on metal surfaces, enhancing aesthetic appeal. These abrasives are excellent for applications requiring minimal material removal and surface conditioning.

- Sinterball and Vegetal Media: Sinterball, a type of soft shot, and vegetal media, made from natural materials like nutshells and seed husks, offer eco-friendly alternatives for surface preparation. Their biodegradable properties and softer impact make them suitable for delicate surfaces and environmentally sensitive applications.

Complementary Use with Metallic Abrasives

It's important to recognize that non-metallic abrasives complement rather than replace metallic abrasives. Each type of abrasive media has its specific applications based on the required surface finish, material properties, and blasting objectives:

- Metallic abrasives, such as steel shot and grit, are preferred for their aggressive action in removing heavy scale, rust, or old coatings. They are unmatched in applications demanding high efficiency and deep surface preparation.

- Non-metallic abrasives shine in scenarios where the blasting process must be controlled to avoid altering the surface profile significantly. They are the media of choice for finishing, soft cleaning, or when working with non-ferrous materials to prevent ferrous contamination.

Choosing the Right Abrasive: The Importance of Expert Guidance

The decision to use non-metallic versus metallic abrasives depends on a thorough understanding of the project requirements, surface materials, and desired outcomes. Expert guidance is crucial in selecting the right abrasive media to ensure optimal results. Specialists can offer insights into the best practices for using non-metallic abrasives for soft cleaning and surface finishing, helping to achieve the desired aesthetic without compromising the material's integrity.

Professionals can also advise on the efficient use of metallic abrasives for more demanding surface preparation tasks, ensuring that both types of media are utilized to their fullest potential within their respective applications.

Conclusion

Non-metallic abrasives play an essential role in soft cleaning and enhancing surface aesthetics, offering a gentler alternative to metallic abrasives for specific applications. By understanding the unique advantages of each type of abrasive media and seeking expert advice, professionals can select the most appropriate abrasive for their blasting needs. Whether for delicate surface finishing or aggressive material removal, the informed selection of abrasive media is key to achieving superior surface treatment outcomes.