Cut wire is a popular abrasive used in a variety of surface preparation applications, particularly in shot peening. However, not all cut wire is created equal. There are significant differences between As-Cut and Conditioned Cut Wire, which can greatly impact the performance, surface finish, and overall effectiveness of the shot peening process. In this article, we’ll explore the key differences between As-Cut and Conditioned Cut Wire, the specific applications where each type excels, and why understanding these distinctions is crucial for achieving the desired results.

Understanding As-Cut Cut Wire

What Is As-Cut Cut Wire?

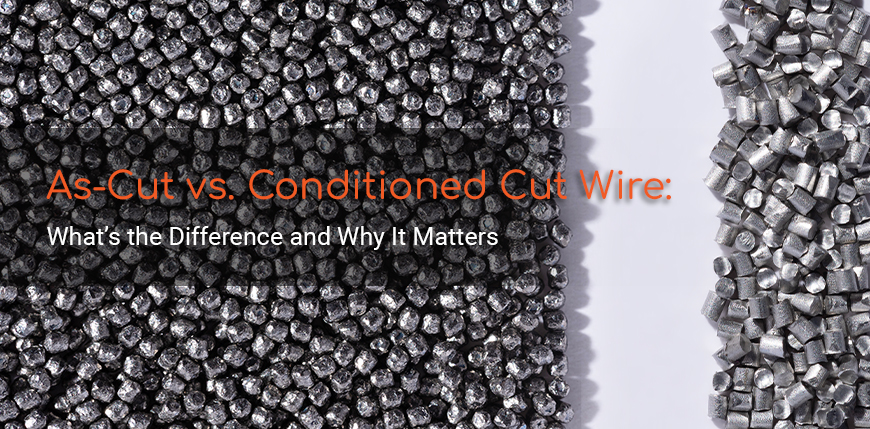

As-Cut Cut Wire is produced by simply cutting wire into small lengths without any further processing or shaping. This means that the cut wire retains its sharp edges and cylindrical shape, making it highly effective for certain cleaning and surface preparation applications.

Applications of As-Cut Cut Wire

- Steel Cut Wire: As-Cut Steel Cut Wire is commonly used in cleaning applications where the aggressive action of the sharp edges is needed to remove contaminants, rust, or scale from metal surfaces. This type of cut wire is often used in heavy machinery maintenance and foundry operations.

- Aluminum Cut Wire: As-Cut Aluminum Cut Wire is preferred for cleaning aluminum components, particularly in industries where maintaining a high level of cleanliness is crucial. Although it is more expensive than other materials like Stelux CN, it offers superior performance in terms of surface finish and cleaning efficiency.

- Stainless Steel Cut Wire: Used both for cleaning and peening applications, As-Cut Stainless Steel Cut Wire is ideal for industries like automotive and aerospace, where preventing ferrous contamination is essential.

The Advantages of Conditioned Cut Wire

What Is Conditioned Cut Wire?

Conditioned Cut Wire undergoes additional processing after being cut to length. This processing rounds off the sharp edges of the wire, resulting in a more uniform and less aggressive abrasive. There are different grades of conditioning, each offering unique benefits depending on the application.

Grades of Conditioned Cut Wire:

- G1 (Rounded): In this grade, the cut wire is rounded off to create a smooth, cylindrical shape. G1 Conditioned Cut Wire is ideal for applications requiring moderate surface roughness and stress distribution. It offers a balance between cleaning efficiency and surface stress relief.

- G2 (Potato-Shaped): G2 Conditioned Cut Wire has a somewhat rounded but irregular shape, resembling a potato. This grade is suitable for applications where a bit more surface texture is needed without being overly aggressive. It is often used in applications that require a moderate degree of surface roughness and stress relief.

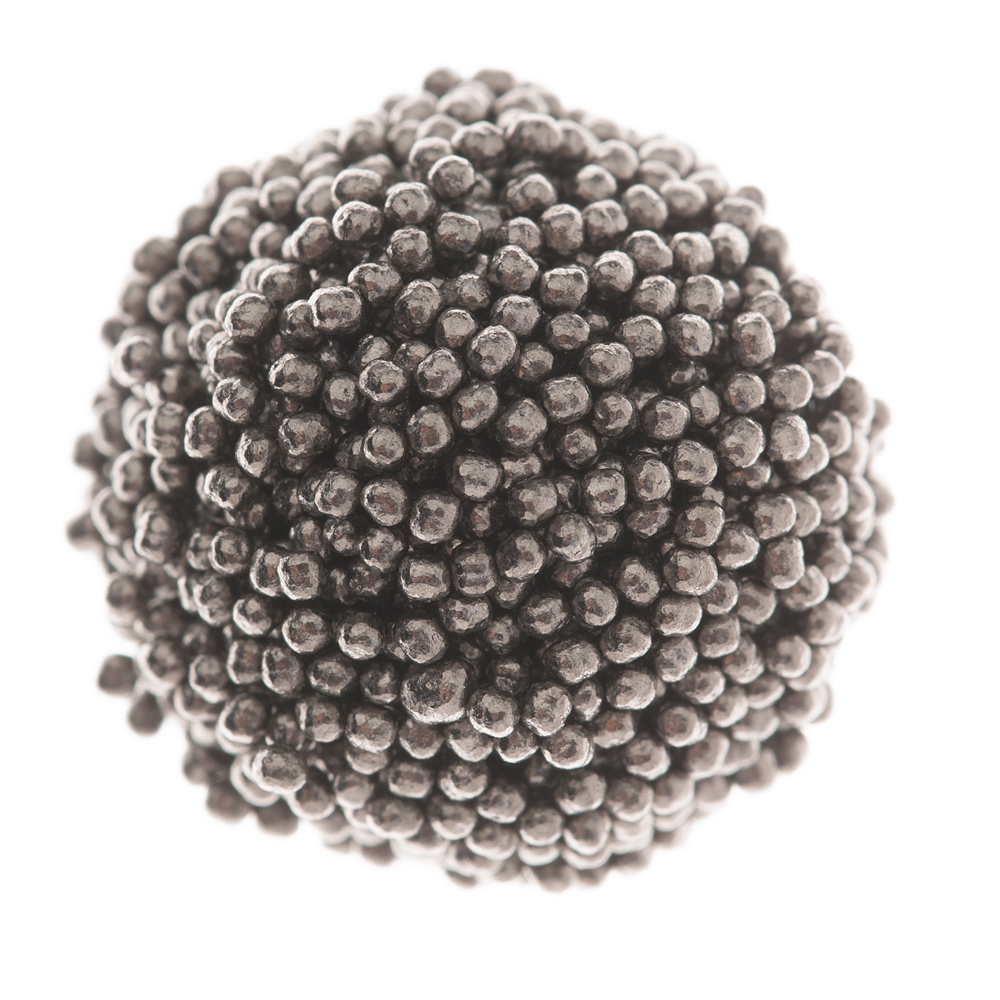

- G3 (Spherical): G3 is the most refined grade, where the cut wire is conditioned into a near-perfect spherical shape. This grade is used in shot peening applications that demand high precision and uniformity in stress distribution. G3 Conditioned Cut Wire is particularly important in aerospace and automotive industries where consistent performance and durability are critical.

Impact on Surface Finish and Performance

Surface Roughness

The choice between As-Cut and Conditioned Cut Wire has a significant impact on the surface roughness of the treated component. As-Cut Cut Wire, with its sharp edges, tends to produce a rougher surface profile, which can be beneficial for certain cleaning applications but may not be suitable for shot peening where a smoother finish is often desired. On the other hand, Conditioned Cut Wire, particularly G3, produces a smoother surface, which is crucial for applications that require a fine finish and precise stress control.

Stress Distribution

In shot peening, the goal is to introduce compressive stress on the surface of a component to enhance its fatigue resistance. Conditioned Cut Wire, especially the G3 grade, excels in this area by providing a uniform and consistent impact, which translates to even stress distribution across the treated surface. This uniformity is essential in critical components, such as those found in aircraft and high-performance automotive parts, where even small variations in stress distribution can lead to premature failure. Remind that residual stress transfered to the part is usually from 0 to 0.2mm below the surface of the part, which means, if you use an aggressive cut wire shape, there is a risk to dig into the surface and to reach the layer where there is no stress remaining. Even if it’s only one point, the result of your shot peening process will be useless because of course the part will break here and nowhere else

Durability and Cost Efficiency

While As-Cut Cut Wire is effective for certain applications, it tends to wear out faster than its conditioned counterparts due to its sharper edges and more aggressive action. Conditioned Cut Wire, particularly those that have undergone heat treatment (such as HD Cut Wire), offers greater

durability and reduced consumption. This makes Conditioned Cut Wire more cost-effective in the long run, as it requires less frequent replacement and delivers more consistent results over time.

Industry Standards and Applications

Automotive and Aerospace Standards

Conditioned Cut Wire is often used in industries with stringent quality standards. For example, VDFI 8001 and SAE J441 are key standards in the automotive industry, with VDFI being prevalent in Europe and SAE in America. These standards guide the selection and use of cut wire in shot peening to ensure consistent and reliable performance.

In the aerospace industry, AMS 24-31/8 is the standard for shot peening, particularly with G3 Conditioned Cut Wire. This standard ensures that the peening process delivers the required surface finish and stress distribution to meet the demanding requirements of aerospace components.

But despite of its high efficiency, the As cut cut wire is definitely banned from all shot peening applications because its sharp edges can damage the surface and reach the non-stressed layer of material

Conclusion and Expert Guidance

Choosing between As-Cut and Conditioned Cut Wire depends on the specific requirements of your surface preparation or shot peening application. While As-Cut Cut Wire offers aggressive cleaning action, Conditioned Cut Wire provides greater control over surface finish and stress distribution, making it the preferred choice for high-precision applications. For those looking to optimize their processes, consulting with industry experts can provide valuable insights into selecting the right type of cut wire for your needs, ensuring that you achieve the best possible results in terms of both performance and cost-efficiency.