Optimizing Airblasting Operations: The Importance of Precision in Monitoring Tools

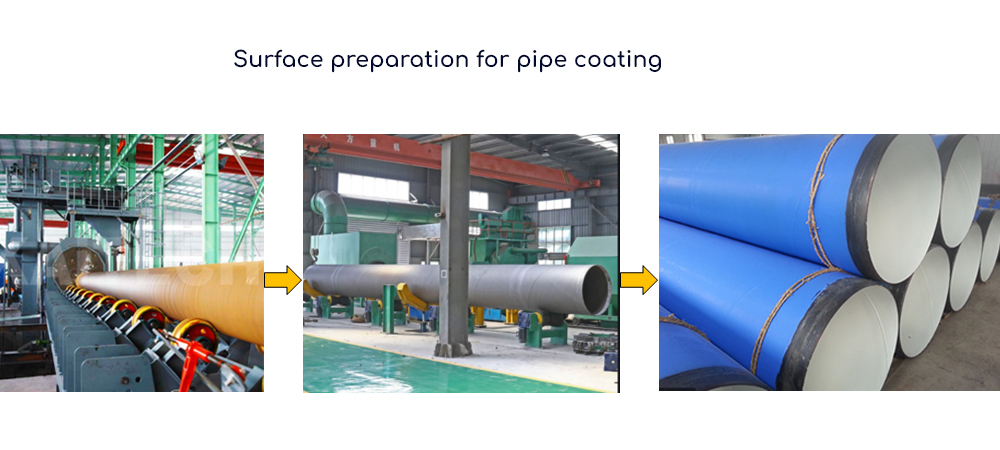

Airblasting operations are a critical component of surface preparation and finishing processes, demanding meticulous control over various parameters to ensure optimal outcomes. The effectiveness of airblasting is profoundly influenced by factors such as pressure, nozzle diameter, dust control, cleanliness, and surface roughness. Understanding the "why" behind the need for precise monitoring reveals the significance of achieving desired specifications, which in turn, enhances the quality, efficiency, and safety of airblasting operations.